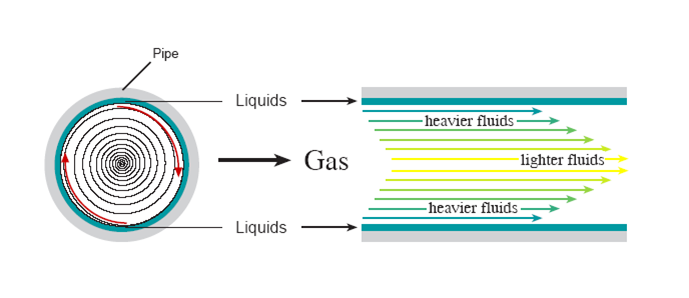

The Vortex surface (SX) tools shape turbulent flow (made up of solids, liquids and/or gases) into a stable, spiraling flow with laminar-like qualities. In doing so, these SX tools help carry the production flow over long distances, turns and changes in elevation. Although the Vortex flow is established quickly, the benefits of the flow from one surface tool can go for over six miles.

Here’s what a flowline looks like without Vortex:

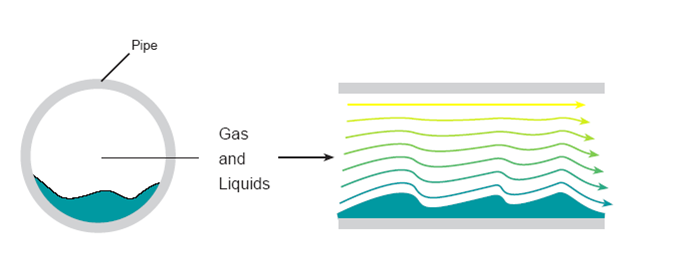

Here’s the flow after passing through the Vortex surface tool:

Vortex surface tools sweep liquids from lines (flowlines, gathering lines and pipelines), thereby preventing freezing in winter, mitigating paraffin build-up and recovering up to 10 times more natural gas liquids (compared to pigging and/or drip systems). In addition to replacing pigs and drip systems, Vortex SX tools also reduce flowing line pressures and compression costs along with improving wells on plunger lift, thereby allowing for more efficient cycles. Finally, these Vortex SX tools help keep chemical treatments suspended in the gas flow, improving their effectiveness as they stably move through the pipe.

These patented SX tools contain no moving parts and are virtually maintenance free. With no additional power source necessary than the flow itself, the Vortex tools are an energy-efficient, cost-effective, green addition to oil and gas wells.

Vortex SX tools are manufactured to line sizes ranging from 2″ on up and are designed to accommodate working pressures up from 150# to 3000# PSIG. They can be manufactured to accommodate a wide range of pressures and corrosive or hostile environments like H2S or CO2. Please contact us for a free application analysis at 303-761-7570 or through our contact form.

For information on specific tools, choose a surface application below:

In addition, Vortex can reduce the average flowback startup time to the production tanks by as much as a day. By separating out the mud, the Vortex flow cleans the initial slug of production, translating those initial high-production days to the pay meter and profit rather than waste and pollution in the flare pit. This flowback time reduction tool is typically set between the high-pressure separator and the heater-treater.

A large, East Texas independent (in conjunction with a leading flowback and well testing company) placed a Vortex flowback time reduction tool between the high-pressure separator and heater-treater and was able to reduce the production lost to the pit by one day, generating an additional $500,000 in previously “lost” production and significantly reduced the emissions impact.