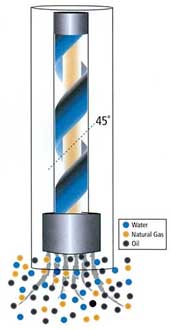

Vortex downhole (DX) tools unload liquids and extend the decline curve of a well by allowing the well to flow below the critical rate (down to 50-75% of Turner and Coleman). By allowing the well to free flow longer, the return on investment (ROI) of a well is enhanced and flowing bottom hole pressure is reduced by 10-15%, major intervention is delayed and, if the well has more production to give, the DX series of tools can help improve production efficiency. Finally, the stable flow set up by the DX tools also helps reduce the need for soaping or, if excessive soaping has occurred, can help lift this excessive surfactant trapped at the bottom of the well. With pump off caps and wireline retrievable applications, several of these DX tools can be run in live, thereby enhancing productivity without killing the well.

The wireline retrievable (DX-WR) tool is also ideal for underground gas storage facilities, where the tool improves the amount of gas recovered, extends the flowing cycle, improves liquids recovery and, in some cases, recovers gas rates beyond that which was injected in the previous season.

These patented DX tools contain no moving parts and are virtually maintenance free. With no additional power source necessary than the production, the Vortex tools are an energy-efficient, cost-effective, green addition to oil and gas wells. Whether installed vertically or in horizontal laterals set in a new well or intervening in a declining well, the Vortex DX tools enable a well to free flow more efficiently and for longer.

Vortex end-of-tubing (DX-EoT) tools can be installed on standard tubing sizes from 2.375” on up, as well as on various sizes of both steel and poly coil tubing from 0.5″. The Vortex slickline retrievable (DX-WR) tools can be installed in standard tubing sizes of 2.375” on up. The downhole tools can be manufactured to accommodate a wide range of pressures and corrosive environments. Please contact us for a free application analysis at 303-761-7570 or through our contact form.

For information on specific tools, choose a downhole application below:

In addition, Vortex has velocity string (DX-VS) tools for use in conjunction with coil tubing in relatively shallow wells and plunger-lift (DX-PL) tools for assisting plunger lift systems during the free flowing period. These DX-VS and DX-PL tools enable the same benefits—flattened decline curve, reduced

flowing bottom hole pressure, reduced surfactant use, and improved production (dependent on the well)—as the other Vortex downhole tools. Additionally, the heavy bullnose end to the DX-VS (pictured left) acts as a centralizer for the velocity string tubing.

For heavily declined wells that still have a lucrative production stream, this DX-PL acts as a final value enhancer. Ideal conditions include gas production with associated water and sufficient energy (velocity) to create Vortex’s helical flow. For wells prone to salt accumulation or paraffin, the DX-PL tool can also improve the efficiency of plunger cycle and reduce resistance due to calcification or paraffin.